Deploying a new Terminal Operating System (TOS) at a terminal is a project that completely shakes up an organization. It impacts the whole terminal, implying huge challenges and unforeseen problems to overcome.

But it is also an opportunity to introduce changes in the existing work procedures, to apply new automation methods and to provide new tools for decision making that will all lead to efficiency improvement and safer systems. For a manual-operated terminal, automating Container Handling Equipment (CHE) management is not the only way to get productivity improvements.

In this article we will explore how automating previously manual tasks can lead to boost TOS productivity at a terminal and achieve safer operations.

Cosco Shipping Ports Iberian Valencia Terminal is in the process of migrating its existing TOS to the new TOS. New tools have been developed on top of the new TOS to extend its capabilities to improve yard operations.

A modern Graphical User Interface (GUI) has been created for CHE operators in their Vehicle Mounted Terminals to make their work easier and error prone, by means of automation and decision helpers. An advanced fleet management system has been deployed to get a realtime overview of Terminal Tractor (TT) activity, while automating non added value tasks and TOS reporting.

These systems will boost the terminal performance. Long experience in operations has been used to avoid the most typical human errors, like dropping a container in an incorrect position or picking a wrong work instruction. Automating and helping with the most common TOS/CHE driver interactions will reduce non added value tasks to allow for better usage of the operator time, concentrating on driving and ensuring the accuracy of TOS information. The efficiency of terminal operations grows spectacularly when TOS is enhanced with these advanced tools.

ADVANCED CHE GUI FOR YARD EQUIPMENT

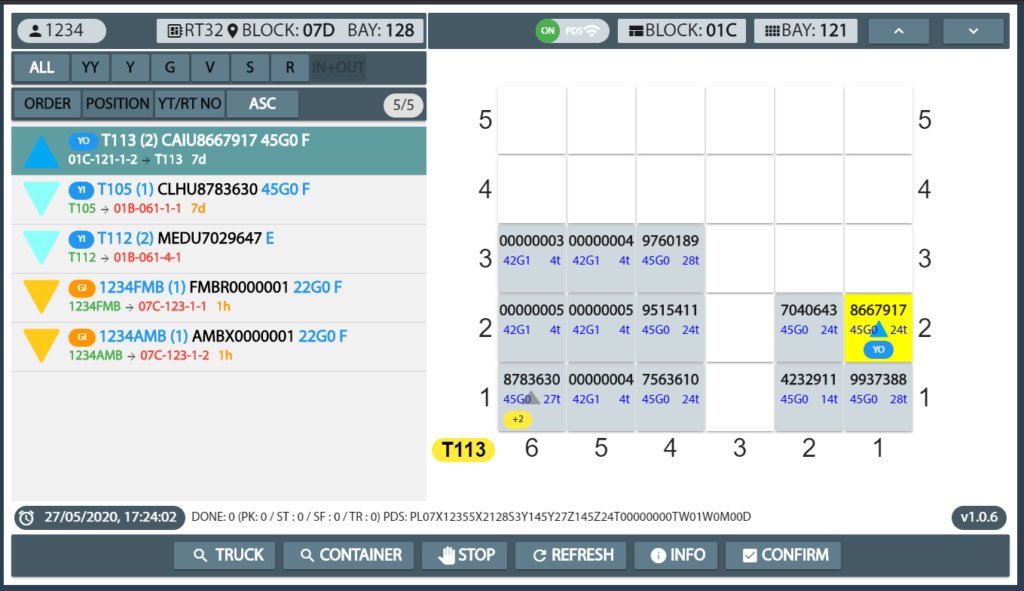

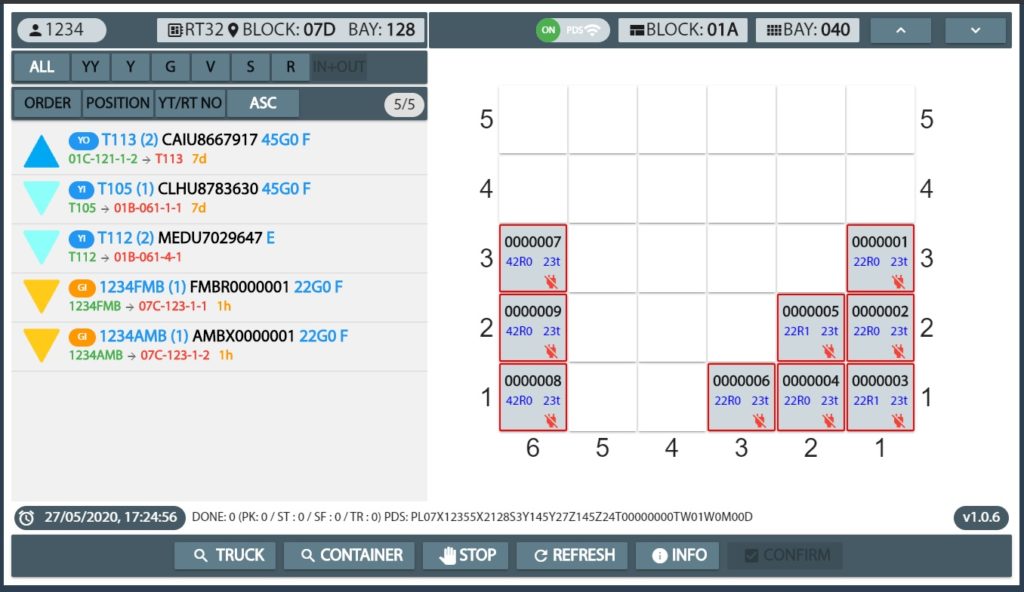

The CHE GUI offers the Yard Equipment operators an intuitive view of the work instructions and the yard sections. Linked with a Position Determination System (PDS), in this case SICE´s Z-Tracer, it allows for an onthe-spot picture of the work to be carried out with real time updates. Careful usability features have been included to give the most useful information at a glance.

Related TOS work instructions are shown to the CHE operator along with the section view to help the operator to have visibility of next actions to perform. Control checkup is automatically and constantly being done, avoiding the most common mistakes like selecting a work instruction for lifting a container at a stack with another container stacked on top of it, or choosing a work instruction for dropping a container “in the air”, while the bottom container has not arrived yet at the CHE.

One of the most common sources of errors in TOS inventory comes from an incorrect container dropping or lifting at yard. The advanced CHE GUI tackles this situation by automating twist-lock operations. The integration with the PDS allows to have a real-time position of the spreader as well. If the spreader location does not match the container position in the work instruction, and twist-lock control function is enabled twist-locks are prevented to operate. Therefore, if the operator tries to drop a container in a different section, stack or tier than the position provided in the work instruction, twist-locks will not be able to release, and a warning message will be displayed to the CHE operator. If this functionality is disabled, twist-lock operations will be granted, however the position will automatically be updated in the TOS, resulting on a 100% of accuracy in container inventory.

Integration with the PDS plus TT’s Radio Frequency Identification (RFID) tag reading offers enhanced control tools and process automation for work instruction identification and job promotion. For instance, if the CHE operator tries to lift a container from an incorrect TT, the system will detect it, not granting twist-lock operation, to ensure that the container will not be lifted from that truck.

Health and safety business rules are automatically applied, as in example, displaying plugged-in reefers to avoid handling containers which may lead to pull out cables, showing up twin carry pairs subject to be loaded in twin or single lift , to ensure the CHE operator adjust properly the gap, etc.

Health and safety business rules are automatically applied, as in example, displaying plugged-in reefers to avoid handling containers which may lead to pull out cables, showing up twin carry pairs subject to be loaded in twin or single lift , to ensure the CHE operator adjust properly the gap, etc.

A complete context information is provided to CHE operators to make their work easier. For instance, TT’s Point of Work (POW) can be seen in the job list, container net load, length or type are available, main work instruction details are highlighted, etc.

A full set of business rules controls and automation are provided in the CHE GUI. These rules combined with the availability of context information offered to the operator and smart advisors, make the operations more efficient and reduce dramatically the manual errors, which results in better productivity and better information quality in TOS. As the business rules tend to change over time when operations procedures are being improved, a configurable drag & drop GUI is provided to IT Administrators for updating the business rules without programming.

These business rules allow the CHE operator to address any unforeseen problem, like TT’s RFID reading error, manual remarshalling, inventory inconsistencies, etc. One big advantage of the CHE GUI is to provide the TOS with all the necessary information to keep yard inventory fully updated, preventing future problems that affect productivity.

With the new Advanced CHE GUI, the operator focusses on driving and manual tasks to be accomplished, while the system automates a lot of check-ups and TOS interaction to boost productivity and keep the yard inventory properly updated.

ADVANCED FLEET MANAGEMENT SYSTEM

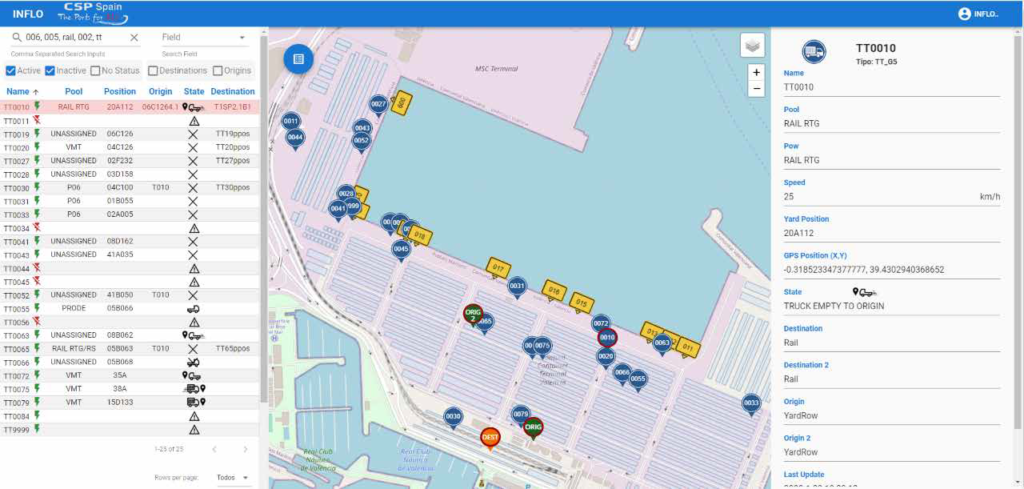

Terminal Trucks at CSP have been equipped with Orbita’s black-box devices, which are in fact IoT gateways, that gather, among other signals, GPS location. These locations are being updated and sent every second to a central stream processor to have the fleet location permanently up to date.

Once the exact location of each TT is known, dynamic geofencing rules are being applied related to the assigned work instructions. When the TT arrives at the origin location, for instance a Sea to Shore (STS) crane to receive a container, a progress update is automatically reported to the TOS. When the TT reaches the destination of the work instruction, for instance a CHE to deliver the container, another progress update is automatically submitted to the TOS. This will mean that no manual intervention of the TT driver will be needed as job-stepping will be a full automated process.

Not only progress is done at the origin and destination. TT’s locations are periodically reported to the TOS at a configurable time, to allow the TOS, to perform a better scheduling and dispatching of work instructions.

Not only progress is done at the origin and destination. TT’s locations are periodically reported to the TOS at a configurable time, to allow the TOS, to perform a better scheduling and dispatching of work instructions.

To improve further the automation of previously manual tasks, each time the TOS assigns a new work instruction to a TT, the system reconfigures the radio trunking system of the TT to automatically select the radio channel of the POW the driver is driving towards. This is the way to let TT drivers always have available a direct communication with the Quay Crane (QC) operator and QC checker he is going to deliver or get a container.

Less manual and non-added value interactions mean safer operations for the drivers, less mistakes in the operations and less time reporting to the TOS, which all lead to an increase of efficiency and safety in the operations at the terminal.

The fleet management system also allows the Terminal Management to have a realtime picture of TT and STS locations. This graphical view also displays the activity being performed by each TT, their origin and destination for the current work instruction, allowing the Control Room staff members to quickly identify any potential bottleneck, idle TT´s location, queues or how long a TT can take to reach to its destination.

CONCLUSION

For a non-automated terminal, the path to improve efficiency and safety is not only automating CHE handling and reducing labour cost. Making things easier and simpler for the CHE operators and automating non added value tasks, will provide efficiency and safety improvements at an affordable cost.

Integrating real-time operation into a dashboard, along with updated activity visualization, also will help the Terminal Management to take better decisions, increasing the overall performance of the terminal.

ABOUT THE ORGANIZATIONS

CSP Spain is a leading port operator in Spain with two maritime terminals located in Valencia and Bilbao, as well as two intermodal terminals, one in Zaragoza and the other in Madrid, services that it complements with its intermodal operator.

Prodevelop is a 25-year experience company highly specialized in ICT solutions for the maritime industry, which prides itself on its ability to offer innovative and flexible solutions, specially designed to meet the requirements of port authorities and terminals. It offers comprehensive port information system platforms and terminal optimization through automation.

ABOUT THE AUTHORS

Iván Deosdad is an established Senior Port Professional with expertise in Operations, Automation and Process Excellence implementation in the Port industry, having worked previously at Hutchinson Port Holdings and DP World holding different senior management positions and joining CSP Spain in February 2016 as Director of Projects Department.

Fernando Martí-Belda is a Telecommunication Engineer with a MSc. in Automation Design and a MSc. in data Analysis. With 7 years of experience in the Industry, he works in CSP Spain Projects Department leading all TOS integration tasks.

Miguel Montesinos is a Telecommunication Engineer MSc. and holds an Executive MBA. He has been working at Prodevelop for the maritime sector during the last 25 years, being CTO and Innovation Manager. He is currently the CEO of Prodevelop, leading the expansion of the company.

PUBLISHED

This article has been published at Port Technology e-Journal (https://www.porttechnology.org/editions/automation-innovations/)