Ángel Martínez Cavero – Prodevelop, Valencia (Spain)

María José Villalobos Gómez – Prodevelop, Valencia (Spain)

Jesús Medina Blanco – APBA, Algeciras (Spain)

A complex business process in which actors from different companies interact in a coordinated manner can never be more efficient without first reaching an understanding between the different actors involved. The synchronisation of maritime traffic, common decision-making, a complete view of the process thanks to the exchange of standard information and the reduction of the gap between estimates and actual planning are some of the challenges that remain, and the key to solving them is collaboration. In this article, the authors describe the process they have been developing to design, develop and implement a collaborative solution that guarantees operational excellence in the Port Authority of the Bay of Algeciras (APBA), one of the main ports of reference in Europe.

Introduction

Port communities are complex ecosystems in which a significant number of actors interact to offer high value-added logistics services under dynamic planning and strict cost control. Due to strong competition, they must be operated to achieve high productivity rates, ensuring daily operations and meeting standards in terms of quality of service, reliability and safety. Of all the casuistry available for the maritime transport of intermediate goods, container ships stand out. Although the port sector has played a fundamental role during the recent health emergency by ensuring uninterrupted delivery of basic and essential goods, events such as the one experienced in the Suez Canal highlight the fragility of a system where any unforeseen event has a global impact on the current distribution model.

Figure 1 – Inactive vessels drifting in front of a port- Source: Cadena de Suministro

There is also a strong commitment by formal institutions to reduce CO2 emissions into the atmosphere from ships. Through the IMO (International Maritime Organisation), a global decarbonisation strategy is being promoted with the aim of drastically reducing the CII (Carbon Intensity Indicator) levels for all shipping. (IMO, 2021) . The action plan sets mandatory standards to meet certain levels of CII and greenhouse gases (GHG). The aim: to reduce emissions of (1) CII by 40% by 2030 and 70% by 2050, and (2) annual GHGs from global international maritime traffic by 50% by 2050. To meet these expectations, shipping lines are considering three strategies: (1) use of more environmentally friendly fuels, (2) use of energy-efficient alternative propulsion systems, and (3) intelligent, real-time adaptation of the ship’s speed during its voyage to match the actual operational context.

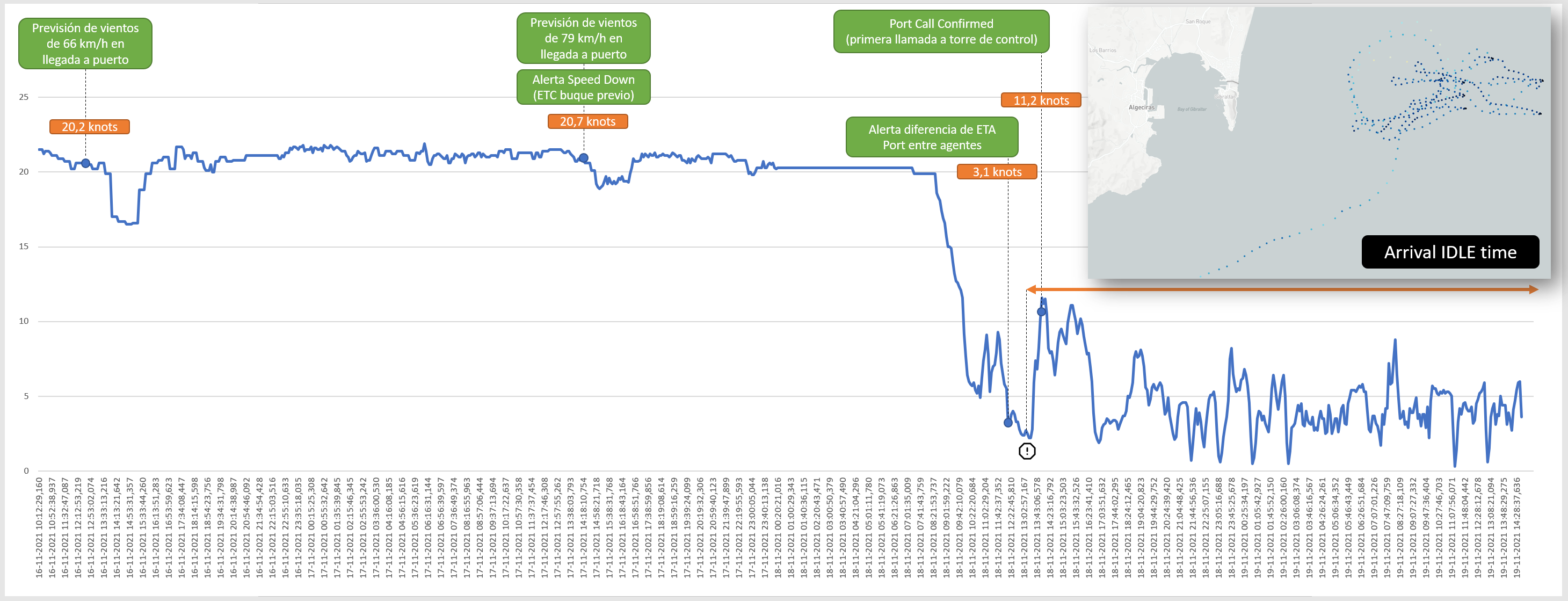

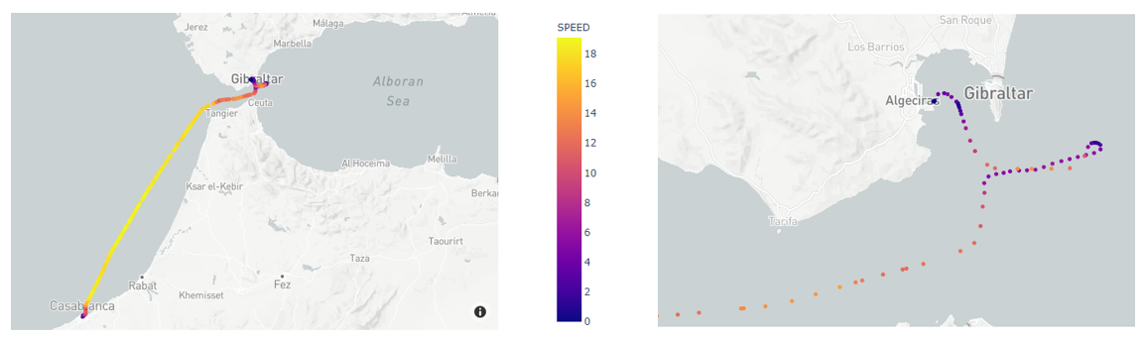

An internal study carried out by Prodevelop and the APBA identified that in 2020 a significant number of container ships intending to access the Bay of Algeciras had to wait to enter the port, the main reason for waiting being the unavailability of the destination berth. Although the casuistry of unforeseen events that can occur during a ship’s voyage is by no means negligible, if we delve a little deeper we find that it is common for ships to sail at high speed only to discover at their destination that the quay where they are to berth is not available. This causes downtime for the port community in general and for shipping companies in particular.

Figure 2 – Container ship waiting to be served at the APBA (2021) -Source: Own elaboration

The concept of CDM (Collaborative Decision Making) does not originate from the maritime industry, as it is used in other industrial sectors (e.g. aviation). The popularisation of this concept (i.e. Port CDM) in the academic and industrial world led to the emergence of a series of open initiatives (e.g. PCO, DCSA and IPCDMC) composed of the main leaders of the sector whose objective is to define, without ambiguity, each and every one of the processes, actors and roles involved in the loading and unloading of container ships. The resulting recommendations are de facto standards that further the standardisation, quality and supervision of data to enable the exchange of information between the different entities, as well as to enable the different technology providers to design and develop globally accepted solutions.

Objectives

Posidonia Port CDM is a technological solution that helps the different agents that make up a port community to manage and operate, efficiently and safely for both their personnel and the environment, the calls of container ships by means of a collaborative tool that guides users in decision-making, reducing uncertainty and providing a global vision of the entire process. The relationship with the APBA and the rest of the actors in the Port Community has enabled validation of both the technological solution and the proposed business model. Likewise, the fact of collaborating with the main working groups (e.g. DCSA or PCO) ensures the validity of the results internationally, as it guarantees that the procedures are subject to the approval of a standard that looks after the common interests of the industry, without opting for a specific technological solution.

Results

Although it is true that each port has a different casuistry with particular characteristics, having a tool such as the one proposed in this work will not only allow first-hand knowledge of what is happening in real time in a port, but will also make it easier for the different agents involved to be informed of possible delays and unforeseen events that may occur in the previous port or even on the way to the next one, since these delays have a major impact on the operations themselves. An active collaboration system such as Posidonia Port CDM is capable, automatically and in advance, of generating an alert informing that the ship’s speed is inadequate and does not conform to the expected operational reality of the container terminal where the ship should dock to be operated.

Figure 3 – Inadequate crossing speed according to the end of operations of the vessel preceding it at the quay – Source: Own elaboration

Discussion and conclusions

That the port industry has understood and decided that in order to be able to offer an acceptable service to its customers according to the quality standard demanded by the market, it is necessary to rely on technological systems is a fact that surprises no one today. At this moment (2021) everyone is talking about collaborative environments, the 4.0 economy and CDM systems applied to the port sector because the industry has understood that in order to be able to face the current demanding demands and to be competitive at a global level, it is necessary to cooperate, to work in a coordinated way as a Community and to make decisions based on real information from all the agents involved and that shows the complete process, without biases. The current moment is critical to decide and commit to a solution that provides our economy with the advantages and benefits of CDM systems, that is competitive and powerful at a global level, and that allows our ports to take advantage of the opportunity to pursue operational efficiency.

This work has made it possible to validate the benefits of the Port CDM concept in a demanding and real environment, and has demonstrated that collaboration, through the sharing of significant data between all stakeholders in a business process, as well as the standardisation of common terminology, far from penalising or weakening the sharer, produces significant improvements in the operation of the whole. With the arrival of mega-ship calls in ports becoming an incipient reality, port authorities and other agents in the sector are making real efforts to improve the management of operations.

This article has been published at BIT e-journal, click here to read it.

Posidonia Port CDM (Collaborative Decision Making) is funded by the Ports 4.0 capital program, an innovation initiative by Puertos del Estado and Spanish Port Authorities: